ACME PIPE WINCH

REPLACE LEAD, PLASTIC, GALVANIZED AND COPPER WATER LATERALS

THE ACME PIPE WINCH

SIMPLIFY TRENCHLESS PIPE PULLING

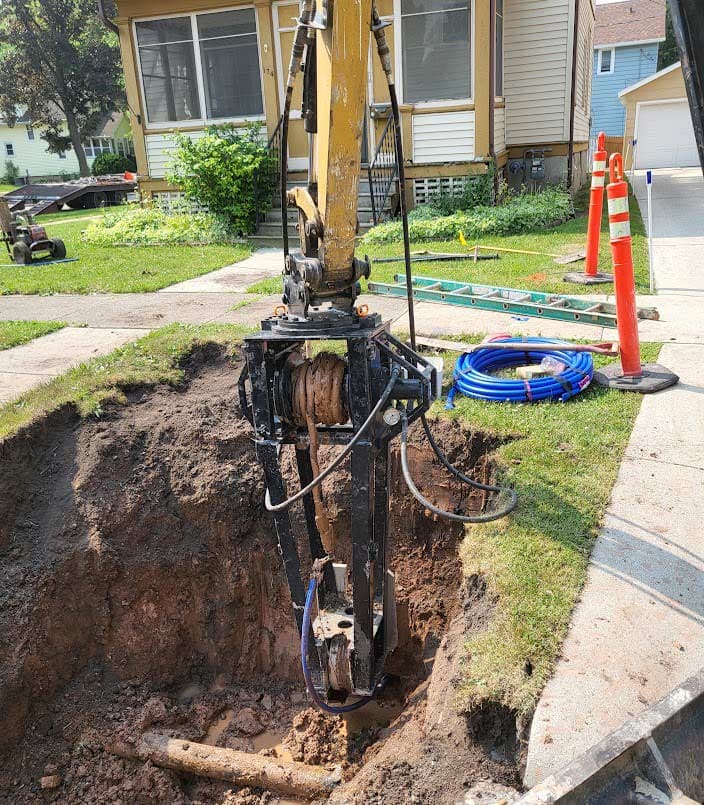

The ACME Pipe Winch Model M2060 is a patented, hydraulically powered pipe-pulling winch that attaches via a quick coupler to your excavator or backhoe. It is designed specifically for Utility Excavators and Municipal Crews to enable the efficient trenchless replacement of utility laterals, simplifying the process while minimizing surface disruption.

Proudly made in the USA, and engineered for versatility, it is compatible to a 3.5 T or larger excavator, or backhoe. The ACME Pipe Winch delivers powerful performance with a line pull capacity of 20,000 lbs. and a line speed of up to 30 feet per minute. Its innovative 360-degree full-rotation capability, lockable in 6-degree increments, ensures precise alignment to the host lateral in various operational conditions.

Designed for reliability and performance, the Acme Pipe Winch is the go-to choice for professionals looking to simplify utility lateral replacement.

WHEN IT COMES TO PIPE PULLING

THE PIPE WINCH AND A COMPACT EXCAVATOR MAKE FOR A GREAT COMBINATION

Maneuverability makes the compact excavator the machine of choice when performing urban utility excavation. But when it comes to using the small excavator for pipe pulling, it may not have the traction force or stick breakout force required to make the pull. Do not bring in larger equipment, combine the the Acme Pipe Winch and the compact excavator to get the job done.

The ACME Pipe Winch has a slender, compact profile which makes it ideal for use in congested site access pits, allowing operations to proceed seamlessly even when in close proximity to other utilities. Being an attachment to your excavator or backhoe, the placement is exact and stable.

POWERFUL, VERSATILE & ECONOMICAL

The Acme Pipe Winch advantages

PULLING POWER

It has the pulling power needed with a rated line pull at 20,000 lbs.

ECONOMICAL

The ACME MAX pulling cables are reusable.

SAFE OPERATION

The tensioned pulling cable remains within the confines of the winch frame and the access pit during the pull.

ADAPTABLE SETUPS

The winch rotates 360 deg. and locks in place for a perfect alignment to the host lateral.

UNIVERSAL FOOT ARRANGEMENT

Pull a water line that is close to a sewer lateral.

STAY IN SPEC

Preserves the original bury depth as the pull is made at a horizontal plane to the existing water line.

ADAPTABLE SETUPS

NEAR A SEWER LATERAL? NO PROBLEM

You can utilize the benefits of the Acme Pipe Winch to pull a water line, even if excavation reveals it to be near a sewer lateral.

The sketches illustrate the different scenarios of water line to sewer lateral arrangements one may expose. The base of the Acme Pipe Winch can be easily field configured with use of hand tools to 3 different setups to afford clearance to a sewer lateral and still apply a powerful pull to the water line. Simply remove the left foot or the right foot and attach the face plate accordingly. If there is no sewer lateral close by, leave both the left and the right foot on and make the pull.

LEAD LINE LEFT - SEWER RIGHT

Scenario 1: Lead line on the left, close proximity to the sewer lateral to the right — remove the right foot, left foot on. Attach the face plate to match.

LEAD LINE RIGHT - SEWER LEFT

Scenario 2: Lead line on the right, close proximity to the sewer lateral to the left — remove the left foot, right foot on. Attach the face plate to match.

LEAD LINE CENTER - NO SEWER

Scenario 3: If the sewer lateral is not in close proximity, both the left foot and right foot will remain on. Attach the face plate to match.

ABOUT ACME TRENCHLESS

REMOVING LEAD LINES SINCE 2018

“I was in the R&D phase on every lead line removal job I was on. I couldn't stop thinking of a better way to pull and remove lead lines — not just for myself but for other Contractors and Municipalities across the country.”

Dave Williams, Founder of ACME Trenchless

HAVE A QUESTION?